Dependable snowplow operation is the result of following good maintenance procedures.

Inspect your plow frequently to ensure all parts are working properly, and establish a schedule for maintenance at regular intervals.

The majority of snowplow operational problems are caused by moisture in the hydraulic system. For best performance, change hydraulic oil biannually, if not annually.

Before each season, check the vehicle battery and electrical system for proper operation. A weak battery, dirty terminals, or faulty charging system may cause improper operation.

Periodically check all electrical connections for proper fit, and remove any corrosion that may be present. Always replace dust caps on connectors when not in use.

Regularly inspect the snowplow headlamps for proper function and aim. Also, inspect all hardware for proper torque value. Replace worn bolts and nuts as needed.

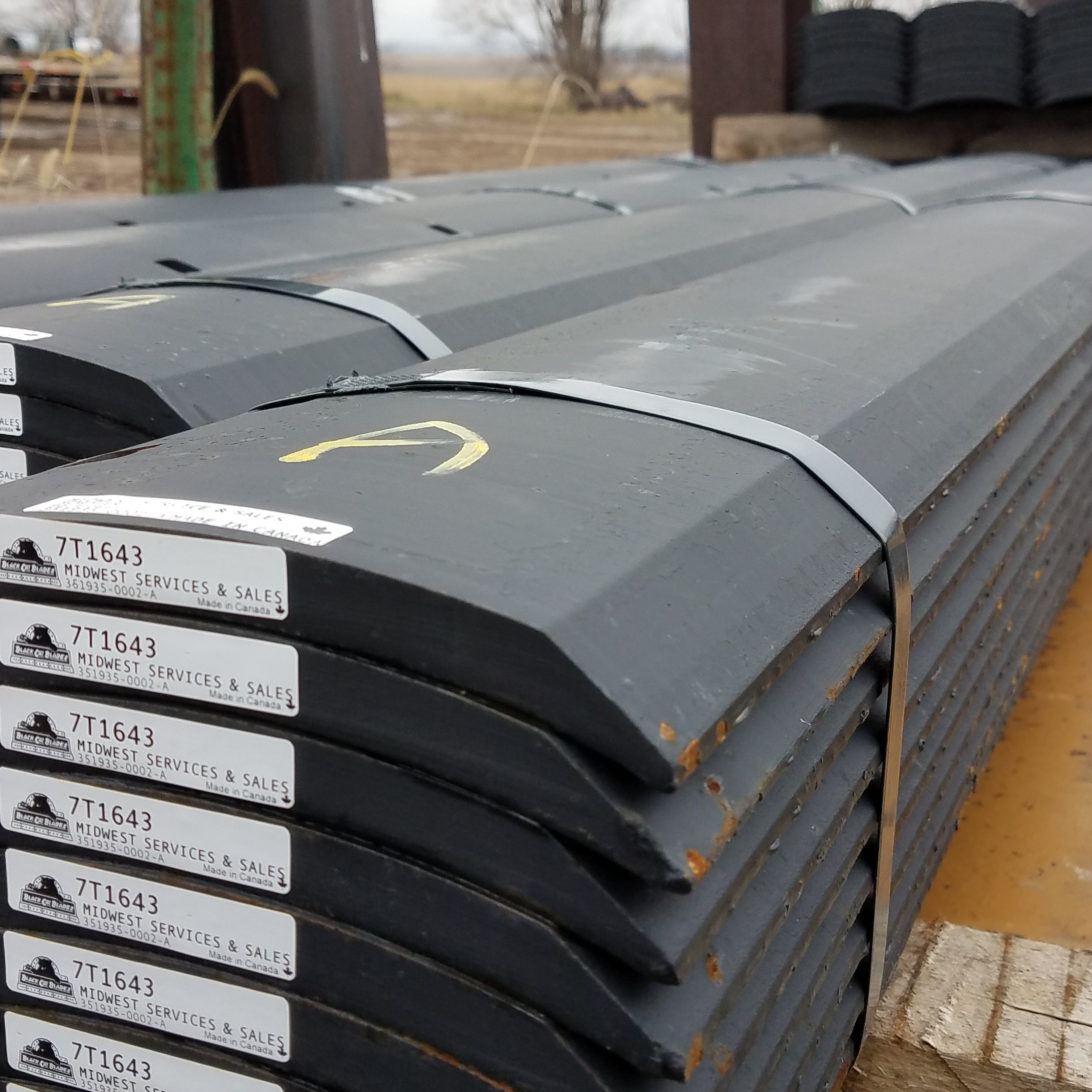

Inspect wear of the cutting edge before every plowing season and frequently throughout the season. Replace the cutting edge before wear reaches the main plow blade.

After each use, and before end of season storage, wash all salt and dirt off the plow. Touch up any chips or scratches in the paint and apply a light coating of grease to extended cylinder rods to prevent corrosion.